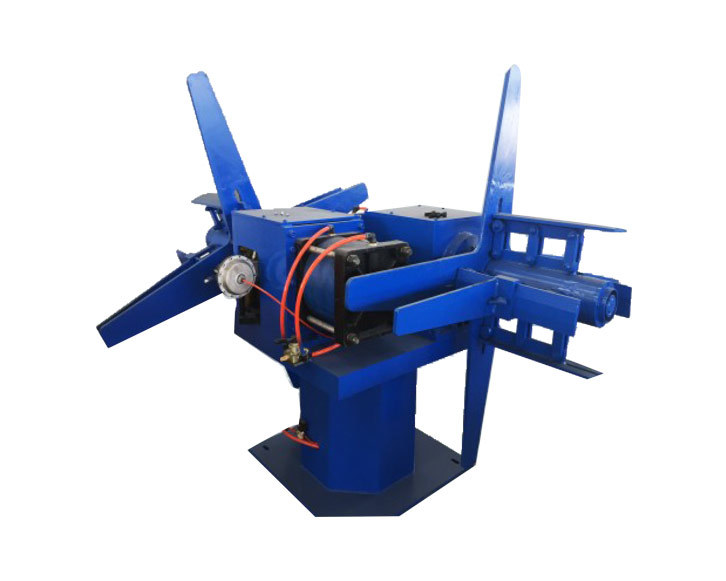

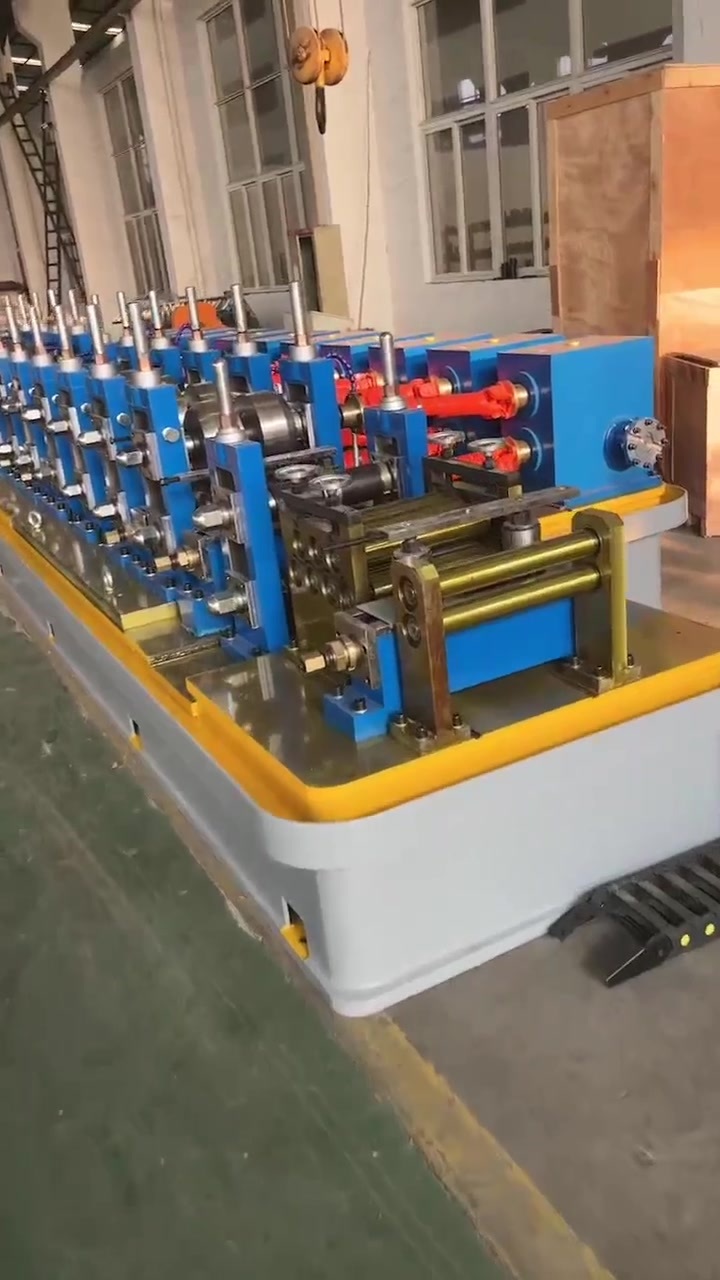

Recommend products

Our company was founded in 1971, in the field of welded pipe equipment has accumulated more than 50 years of design, processing, installation, commissioning experience.

ABOUT US

Company Profile

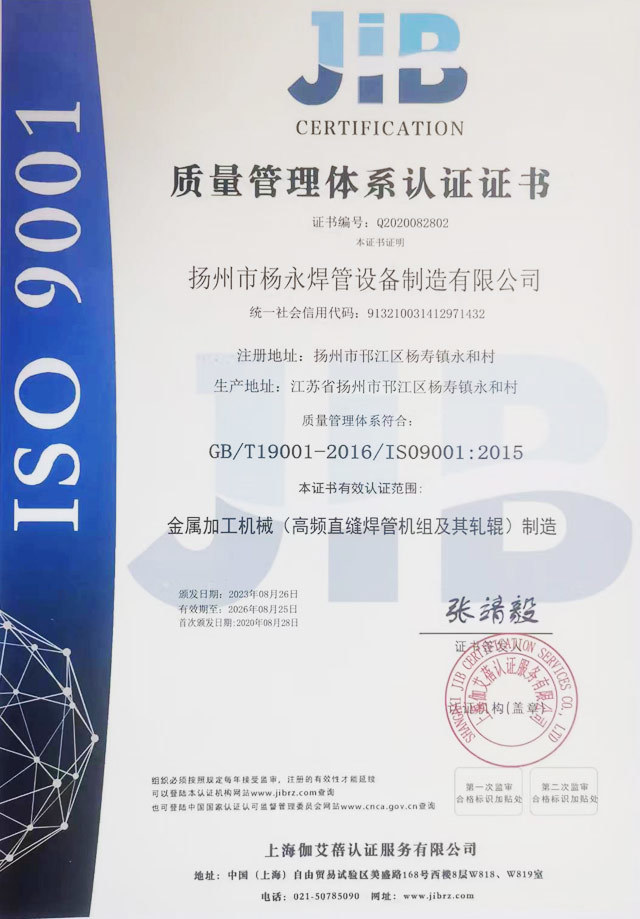

Yangzhou Yangyong welded pipe equipment manufacturing Co, Ltd. was founded in 1971. There are more than 200 employees, including more than 20 scientific and technological personnel. The company occupies thirty-five thousand square meters, and the building area is ten thousand.Six thousand square meters. The existing fixed assets are about twenty milion yuan, scientific and rigorous management, high-quality employees, and strive for improvement.

Learn more →

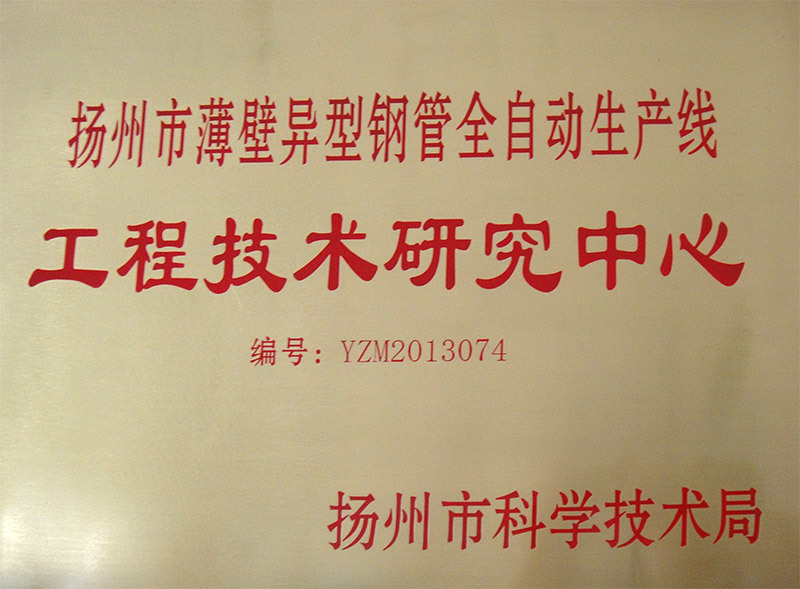

Honor

Partners

Global layout, product applications throughout Asia, North America, Europe and other mainstream markets.

Blog

Unraveling the Wonders of GH Series High Frequency Straight Seam T

Discover how the GH series high frequency straight seam t is revolutionizing industries with innovative solutions.

Unveiling the GH Series High Frequency Straight Seam T: A Game Changer in Welding Technology

Discover the innovative features and benefits of the GH series high frequency straight seam t in our latest product introduction.

Unlocking the Potential of GH Series High Frequency Straight Seam Technology

Explore the wonders of GH series high frequency straight seam technologyechnology in welding and its applications.